Plastic injection molding

● Your reliable partner for plastic injection molding, including mold making and opening molds for production. We offer a wide range of materials and ensure fast delivery to meet your needs. Simply upload your CAD file, and we’ll provide a customized quote.

15%

Nylon PA 66

25%

ABS

10%

HIPP

50%

Others

How we help your business grow

Guarantee

Maximum value

Price

Competitive & Reasonable

Customization

Base on customer preferences

Quality

Never compromise

Delivery

Always on time

24

Quotation in HR

35

Production in DAYS

72

Express service in HR

25

Rush order deliver in DAYS

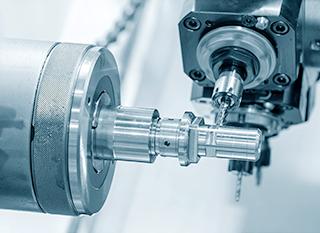

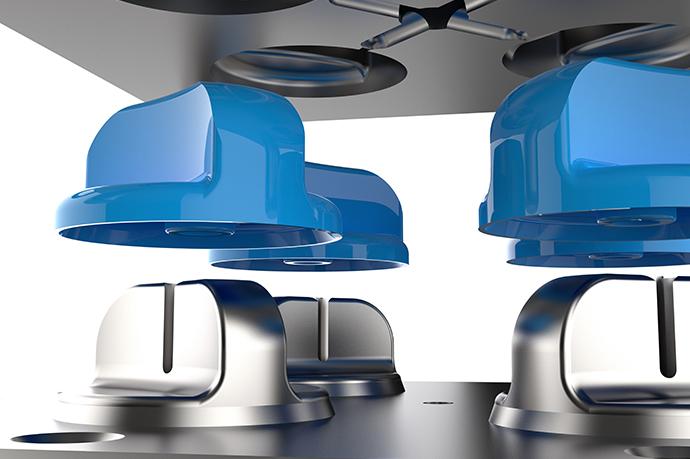

Modern series production

Cost-effective series production using injection molding

Injection molding is a cost-effective process for manufacturing components in large or small series. DMS offers a wide range of plastics with suitable strength and surface quality. They provide special surface finishes and can deliver molded parts quickly using digital workflows.

We do not just provide parts.

We provide answer and solution.

Plastic injection molding

Technical data

| Material thickness: | 0.3 mm – 12 mm |

| Dimensions: | max: 500 mm x 500 mm x 500 mm |

| Component weight: | up to 15 Kg |

| Tolerances: | up to 0.1 mm |

| Closing force: | 20 – 2.500 T |

| Ideal batch sizes: | from 100 piece |

| Tools: | Single cavities |

Our materials

Available materials

| PVC, POM, Nylon PA 6, PA 6.6, PPO, PBT, PPS. |

| LCP, PC, PE, PES, ABS, PP, SAN. |

| PMMA, PS, PET, PC, TPU, TPE. |

Briefly explained

How does injection molding work?

Injection molding begins with heating the raw material, typically plastic granules or powder, until it liquefies. The molten plastic is then injected at high pressure into a mold cavity. Once the plastic has cooled and solidified in the mold, the tool is opened, and the final plastic part is extracted. Additional refinement processes such as polishing, painting, electroplating, and laser marking can be applied to the finished parts.

Surface treatment

We get the best out of your components

Refinement, appearance, protection against wear and corrosion prophylaxis of the turned components are as much part of our core business as the production of components.

-

Liquid coating

-

Vacuum plating ( PVD )

-

Powder coating

-

Electroless nickel

Your partner for all components

Other manufacturing processes

Sourcing easier than ever

Perfect components in 3 steps

1

Get a quote

Send manufacturing drawing and specify order. You will receive your quote within 48 hours.

2

Quality control

We find the right manufacturer, monitor production and take care of quality control

3

Receive components

You receive your quality-tested components including a detailed test certificate.

We go beyond being a supplier.

We are an extension of your success.

Hear from the real MVPs — our customers!

Tony Fred, Senior Buyer

Hi Jim,

We greatly appreciate the exceptional service provided by you, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.

Mich Stark, R & D Engineer

Hi Alice,

Just want to say your outstanding service is super impressive. Your great job on our stainless steel bending case makes our espresso coffee grinder added value. It really makes it look nice, super well done.

Aline Turner, SR procurement

Hi Alice,

We would like to say thank you to you Alice, DMS delivered our parts very fast with excellent quality that is what we are expecting, hopefully you will see our next order very soon, by the way Alice, please say hi to Jennifer for me.

Iris Joe, Engineering Designer

Dear Alice,

Now I can say it is a right decision to move our production from China to DMS, you guys are awesome, all the marine pads looks shinny no scratch founded, it is 8% more expensive compare to China but quality talks, we will keep buying more items from you for sure.

We transform your ideas into reality.