CNC Turning Services

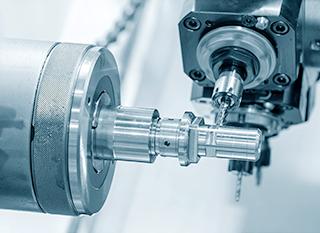

● We produce high-precision CNC turned parts using advanced auto-feed bar systems, Swiss-type, and Japan-type turning machines.

● Our high-speed tooling and state-of-the-art facilities ensure exceptional accuracy, surface finish, and consistency for every custom turning project.

● Materials we work with include aluminum, stainless steel, brass, Titanium 6 Al- 4V , polycarbonate, acetal or medical plastics — ideal for components used in the automotive, medical, robotics, and consumer electronics industries.

45%

Aluminum

15%

Stainless steel

20%

Steel

20%

Others

Turned parts with precision

CNC turning with

on-demand delivery

DMS Group offers streamlined procurement and fast delivery of precision CNC-turned components, upholding the highest quality standards. We machine a wide range of metals and plastics, providing versatile CNC turning solutions for prototypes, one-off parts, and small to large production runs. Our advanced equipment enables us to manufacture high-precision parts such as adaptors, caps, hubs, flanges, rollers, connectors, knobs, plungers, seals, bodies, mounts, guides, supports, bushings, dowels, blocks, couplings, nozzles, and plates.

Applications

We provide custom CNC parts and precision machined components for a wide range of industries, including automobile and automotive components, motor components, RC car components, robotic equipment, inspection instruments, gas devices and flow control components, medical equipment, laser equipment, communication parts, optical components, and bicycle components.

With advanced CNC equipment and strict quality control, we are a reliable precision CNC parts manufacturer, supporting customers worldwide with high-accuracy CNC machining parts tailored to specific functional and tolerance requirements.

We may not be perfect, but our work is honest and results are true.

CNC turning

Technical data

| Available diameters: | 0.8 mm – 5.300 mm |

| Available lengths: | 0.5 mm – 20,000 mm |

| Tolerances: | up to +/- 0.05 mm |

| Surface roughness: | up to Ra 0.8 / Rz3.2 |

| Materials: | Over 600 materials |

| Lot sizes: | from 1 piece |

Explore usable information about steel material Learn more

Discover more about aluminum material Learn more

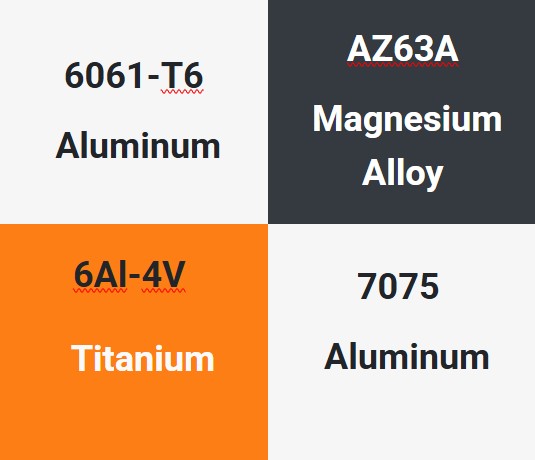

Our materials

Available materials

| Stainless steel series | 300 Series | SUS303, SUS304, SUS304L, SUS316. |

| 400 Series | SUS420J2, SUS430, SUS434, SUS442. | |

| Steel Series | Carbon steel | 12L14, 12L15, 1018, S1020, 1040, 1045. |

| Cr-MO | SCM430, SCM415, SCM435, SCM440. | |

| Ni-Cr-MO | SNCM415, 4140, 4130, 4340. | |

| Aluminum Series | A2024, A5052, A6061, A6063, A6463, A6082, A7075. | |

| Brass Series | CDA3600, CCDA3604, | |

| Plastic Series | EPDM, Delrin, Lexan, Nylon 66, Nylon 6, POM, Peak, PP, PE, Acetal. | |

| Titanium Series | Grade 1 to grade 28 | |

| Magnesium Series | AMS 4375 - AZ31B-O Sheet, plate | |

| AMS 4376 - AZ31B-H26 Plate |

Briefly explained

What Is CNC Turning and How Does It Work?

CNC turning is a precision machining process where a rotating workpiece—typically metal or plastic—is shaped by a computer-controlled cutting tool. This subtractive manufacturing method is essential in industries like aerospace, automotive, and medical device production.

Key CNC Turning Operations

Common operations include:

-

Facing

-

Grooving

-

Threading

-

Taper turning

These are ideal for making cylindrical parts with tight tolerances.

Modern CNC Turning Machines

Advanced CNC lathes feature multi-axis machining (up to 16 axes) and integrated milling tools. They can cut complex features like:

-

Hex shapes

-

Threads

-

Wrench flats

This reduces setup time and improves efficiency.

Why Our CNC Turning Is Trusted

CNC turning is:

-

Accurate and repeatable

-

Fast and cost-effective

-

Used in high-stakes industries

It’s a reliable choice for high-volume production or custom prototyping.

We may not be perfect, but our work is honest and results are true.

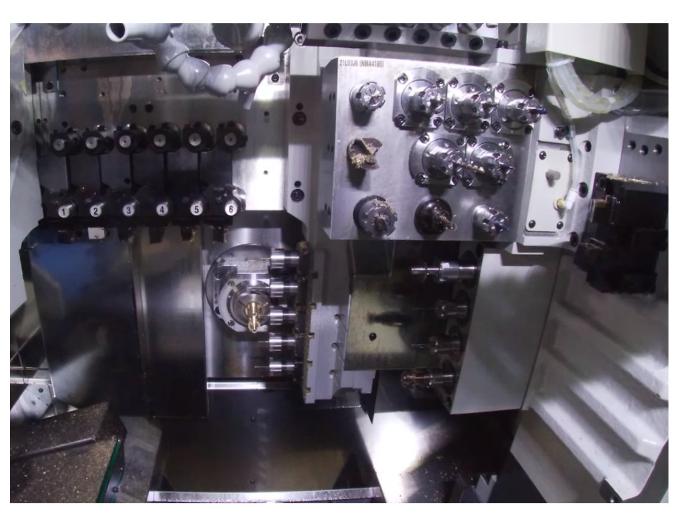

Swiss-Type CNC Turning: Precision Meets Automation

Swiss-type CNC turning is a highly advanced machining process designed for producing complex, high-precision parts—especially in industries like medical, aerospace, and electronics.

What Is Swiss-Type CNC Turning?

Originating in Switzerland and widely adopted in Japanese manufacturing, Swiss-type CNC lathes are known for:

-

Automatic feed systems

-

Up to 20 axes

-

6-sided cutting capabilities

These machines combine turning, milling, and drilling in a single setup, allowing for continuous, hands-off production of intricate components.

Benefits of Auto-Feed CNC Turning

Modern Swiss-type lathes use auto-feed mechanisms to:

-

Reduce manual intervention

-

Improve machining consistency

-

Increase cycle efficiency

-

Handle complex geometries and tight tolerances

This automation makes them ideal for high-volume production of small, detailed parts.

Trusted Technology in Precision Manufacturing

From real-world shop floor experience, Swiss-type turning has proven to be extremely reliable and versatile. Whether you're running medical implants, watch parts, or high-performance connectors, this technology delivers unmatched precision.

CNC Turning FAQs

Discover quick answers on CNC turning questions.

Surface treatment

We get the best out of your components

At DMS, we understand that refinement, appearance, and protection against wear and corrosion are essential aspects of our core business. We not only focus on the production of components but also prioritize the refinement and surface treatment of turned parts. Our expertise extends to providing solutions that enhance the aesthetics, durability, and functionality of the components we manufacture.

-

Sandblasting

-

Paint

-

Anodizing

-

Powder coating

-

Electroless nickel

-

Galvanizing

-

Passivate

-

Chromate

Yes. Our turning capabilities typically handle parts from as small as Ø1 mm up to Ø300 mm, with lengths up to 500 mm, depending on the material and tolerance requirements. For larger or more complex components, we’ll assess feasibility during the quoting stage.

Although this Website may be linked to other websites, we are not, directly or indirectly, implying any approval, association, sponsorship, endorsement, or affiliation with any linked website, unless specifically stated herein.

You should carefully review the legal statements and other conditions of use of any website which you access through a link from this Website. Your linking to any other off-site pages or other websites is at your own risk.

DMS works with over 500+ audited, ISO-certified suppliers, each vetted through strict quality checks. Our team performs first article inspections, uses precision measurement tools, and ensures every part meets spec before shipment. Full traceability and inspection reports are available upon request.

What specific file formats are supported for uploading CAD designs for turning components?

We accept a wide range of CAD file formats for turning parts, including:

-

STEP (.stp, .step)

-

IGES (.igs, .iges)

-

DWG / DXF (2D drawings)

-

SolidWorks (.sldprt)

-

PDF (for dimensioned drawings)

For the most accurate quoting and machining, we recommend STEP files for 3D and PDFs for tolerances and notes.

Yes. We specialize in rapid prototyping and low-volume production, delivering high-precision parts with fast turnaround times. Whether you need a single prototype or a small batch, we tailor our CNC machining services to match your exact specifications.

PEEK (Polyether Ether Ketone) and ceramics offer unique benefits for CNC turned parts:

-

PEEK: A high-performance plastic with excellent chemical resistance, mechanical strength, and thermal stability. It’s ideal for medical, aerospace, and electronic components requiring precision and durability.

-

Ceramics: Known for their extreme hardness, wear resistance, and insulation properties, ceramics are perfect for high-temperature, high-friction, and electrically insulating applications.

Both materials support long-lasting, high-precision components in demanding environments.

Yes. DMS is equipped to machine complex geometries and meet custom design requirements beyond standard specs. With advanced 3-axis to 5-axis CNC machining and a skilled engineering team, we handle tight tolerances, undercuts, multi-surface features, and intricate part designs with precision.

Your partner for all components

Other manufacturing processes

Sourcing easier than ever

Our Simple 3-Step Process for Perfect Components

1

Get a quote

Send manufacturing drawing and specify order. You will receive your quote within 48 hours.

2

Quality control

We find the right manufacturer, monitor production and take care of quality control

3

Receive components

You receive your quality-tested components including a detailed test certificate.

Custom metal parts fabrication experts.

Customer Testimonials: Why Businesses Choose Us

Tony Fred, Senior Buyer

Hi Jim,

We greatly appreciate the exceptional service provided by you, great good looking CNC parts, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.

Mich Stark, R & D Engineer

Hi Alice,

Just want to say your outstanding service is super impressive. Your great job on our stainless steel bending case makes our espresso coffee grinder added value. It really makes it look nice, super well done.

Aline Turner, SR procurement

Hi Alice,

We would like to say thank you to you Alice, DMS delivered our parts very fast with excellent quality that is what we are expecting, hopefully you will see our next order very soon, by the way Alice, please say hi to Jennifer for me.

Iris Joe, Engineering Designer

Dear Alice,

Now I can say it is a right decision to move our production from China to DMS, you guys are awesome, all the marine pads looks shinny no scratch founded, it is 8% more expensive compare to China but quality talks, we will keep buying more items from you for sure.

How we help your business grow

Guarantee

Maximum value

Price

Competitive & Reasonable

Customization

Base on customer preferences

Quality

Never compromise

Delivery

Always on time