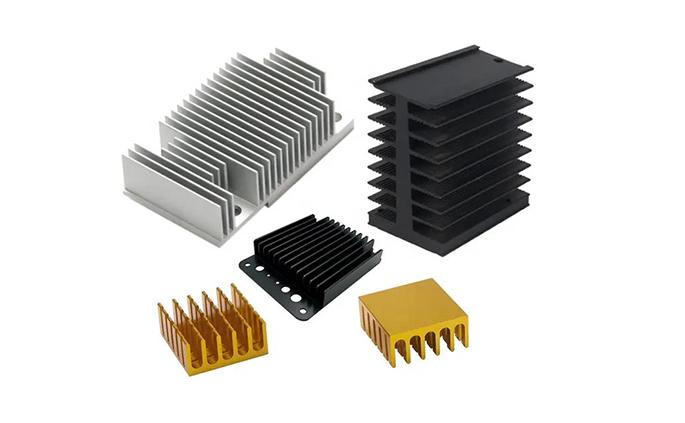

Aluminum extrusion service

● With deep expertise in aluminum and plastic extrusion, we deliver custom extruded products tailored to your design and industry needs.

● From complex profiles to large-scale production, our advanced extrusion technology ensures precision, consistency, and top-quality results at every stage.

50%

Aluminum 6061

35%

Aluminum 7075

15%

Other

How we help your business grow

Guarantee

Maximum value

Price

Competitive & Reasonable

Customization

Base on customer preferences

Quality

Never compromise

Delivery

Always on time

24

Quotation in HR

35

Production in DAYS

72

Express service in HR

35

Production in DAYS

Extrusion parts with on-demand delivery

Cost-effective series production in extrusion

DMS excels in procurement, on-time delivery, and top-tier quality. Our milled parts, shaped by advanced 3-axis and 5-axis milling machines, stand as a mark of excellence. Our material range spans aluminum, stainless steel, and plastics, showcasing CNC milling versatility.

Moreover, our proficiency extends to extrusion parts. Backed by cutting-edge processes, we ensure prompt delivery of accurate components, meeting your needs precisely.

We do not just provide parts. We provide answer and solution.

Aluminum extrusion

Technical data

| Material thickness: | 0.3 mm – 25 mm |

| Dimensions: | min: 3 x 1 x 0.8 mm |

| Component weight: | up to 18 Kg |

| Tolerances: | up to 0,1 mm |

| Closing force: | up to 400 kg |

| Heat treat : HRC, HRB | T4, T5, T6. |

Our materials

Available materials

| Aluminum Series |

A2011, A2024, A2017, A5052, A5056, |

| A6061, A6063, A6463, A6082, A7075. |

|

| Magnesium Series |

AMS 4375 - AZ31B-O Sheet, plate. |

| AMS 4376 - AZ31B-H26 Plate |

Briefly explained

How does extrusion work?

Raw Alloy material is heated and injected at high pressure into a mold cavity. Once cooled and solidified, the final part is extracted. Additional refinements can be applied such as T5 , T6 heat treatment

Extrusion: Material is pushed or pulled through a die to create a continuous profile. The extruded material cools and solidifies, ready for cutting or further processing. Upload your CAD file for an extrusion quote within 2 weeks.

Surface treatment

We get the best out of your components

Refinement, appearance, protection against wear and corrosion prophylaxis of the machining components are as much part of our core business as the production of components.

-

Burnishing

-

Anodizing

-

Chromate

-

Hard anodizing

-

Oxidize

-

Liquid coating

-

Powder coating

-

Electroless nickel

Your partner for all components

Other manufacturing processes

Sourcing easier than ever

Perfect components in 3 steps

1

Get a quote

Send manufacturing drawing and specify order. You will receive your quote within 48 hours.

2

Quality control

We find the right manufacturer, monitor production and take care of quality control

3

Receive components

You receive your quality-tested components including a detailed test certificate

Custom metal parts fabrication experts Contact Us

Hear from the real MVPs — our customers!

Tony Fred, Senior Buyer

Hi Jim,

We greatly appreciate the exceptional service you provided, which has significantly contributed to the success of our research projects and enabled us to achieve breakthroughs in record time.

Mich Stark, R & D Engineer

Hi Alice,

Just want to say your outstanding service is super impressive. The excellent work you did on our stainless steel bending case has added significant value to our espresso coffee grinder. It looks fantastic—super well done!

Aline Turner, SR procurement

Hi Alice,

We would like to thank you. DMS delivered our parts very quickly and with excellent quality, exactly what we were expecting. Hopefully, you will see our next order very soon. By the way, please say hi to Jennifer for me.

Iris Joe, Engineering Designer

Dear Alice,

Now I can say it was the right decision to move our production from China to DMS. You guys are awesome! All the marine pads look shiny with no scratches found. It is 8% more expensive compared to China, but quality speaks for itself. We will definitely keep buying more items from you.

We transform your ideas into reality. Contact