Why Choose Billet CNC Parts for Dirt Bikes?

Introduction

Every dirt bike rider knows the truth: when you’re charging through rocks, sand, mud, and jumps, your bike is only as strong as its weakest part. A failed clamp or a cracked mount can end a race—or worse, cause a serious accident. That’s why more riders, racers, and aftermarket brands are making the switch to billet CNC parts.

At DMS Group Taiwan, we’ve been machining precision dirt bike components for years, helping brands and distributors worldwide deliver products that are stronger, lighter, and built to last. In this article, we’ll explore what billet CNC parts are, why they matter, and how they give dirt bikes the performance edge.

What Are Billet CNC Dirt Bike Parts?

"Billet" refers to components made from a solid block of high-grade aluminum. Instead of being poured into a mold (casting) or pressed into shape (forging/stamping), billet parts are carefully machined on computer numerical control (CNC) machines.

This process allows for:

Extreme precision – tolerances down to microns

Consistent quality – every piece matches the CAD design

Stronger material integrity – no hidden air pockets or weak spots from casting

Greater design flexibility – parts can be customized quickly and updated without new molds

In short: billet CNC parts are engineered, not just manufactured.

The Key Benefits of Billet CNC Parts

1 Strength & Durability

Dirt bikes live in punishing environments—hard landings, constant vibrations, and unpredictable impacts. Billet aluminum’s dense, uniform structure makes it far less likely to crack or fail compared to cast components. Riders trust billet CNC parts because they hold up under real racing conditions.

2 Lightweight Advantage

Performance is all about the power-to-weight ratio. Billet parts can be optimized for strength without excess bulk. A lighter triple clamp or handguard mount means better handling, faster response, and less rider fatigue—critical in motocross and enduro racing.

3. Precision Fit

When installing parts, riders and mechanics notice the difference immediately. A CNC-machined billet clamp or bracket fits exactly as intended, with no wiggle, slop, or stress points. That precision translates to better control, smoother steering, and fewer maintenance headaches.

4. Customization Options

Since billet CNC parts are cut directly from CAD designs, it’s easy to adjust dimensions, add branding, or create unique geometries for OEM or aftermarket applications. For brands, this means faster product development and the ability to differentiate with custom logos, finishes, and styles.

5. Professional Look & Finish

Let’s be honest—style matters. Billet parts aren’t just stronger, they look premium. Clean machining lines, anodized finishes, and laser-etched branding make billet CNC components stand out on any bike.

Common Billet CNC Dirt Bike Parts

At DMS Group Taiwan, we produce a wide range of billet components for motocross and off-road applications. The most popular include:

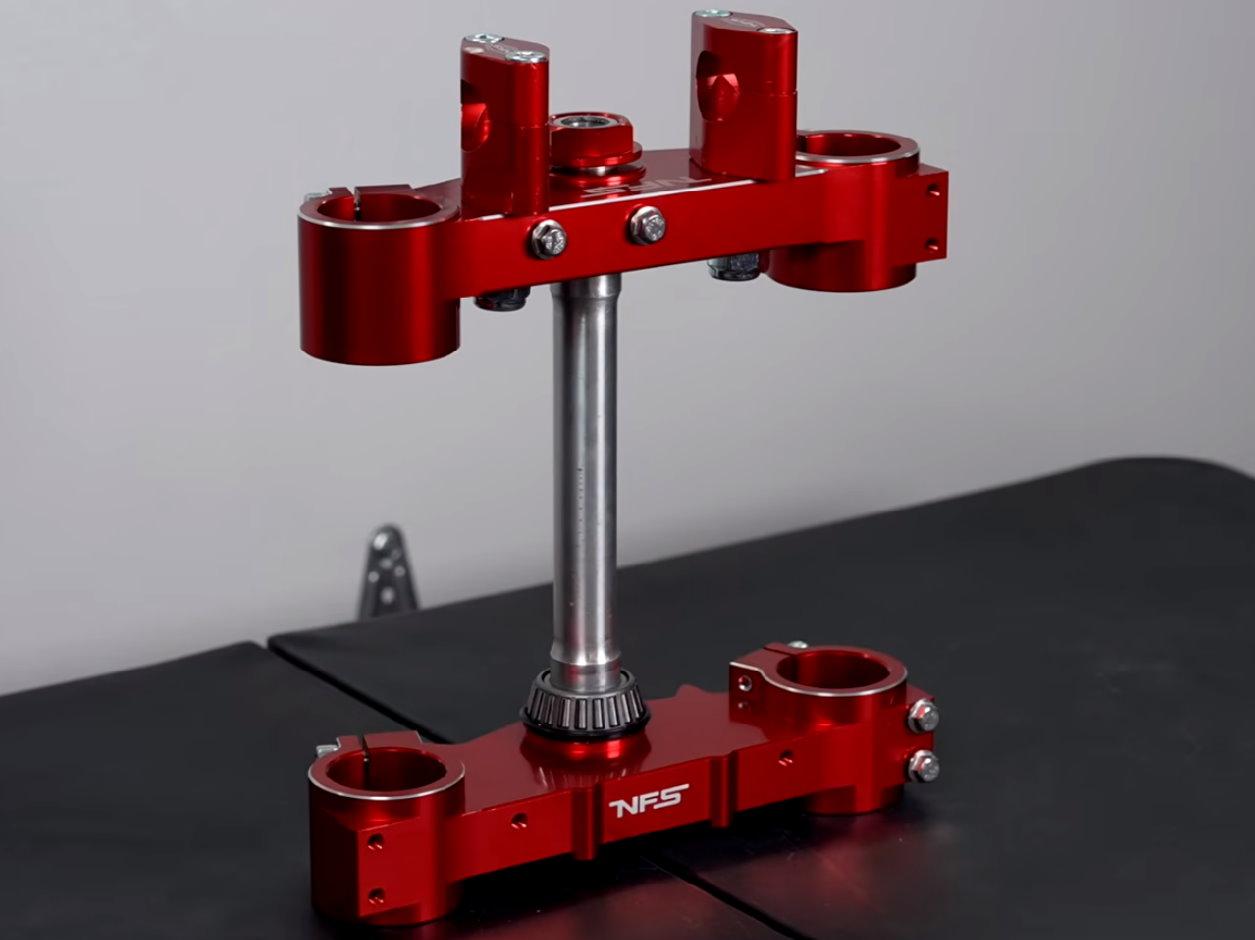

Triple Clamps – improved rigidity and steering response

Handguard Mounts – strong protection without bending or breaking

Handlebar Clamps & Risers – precision fit for aftermarket bars

Brackets & Custom Fittings – tailored solutions for OEM and aftermarket needs

Each part is engineered to withstand the toughest off-road environments while maintaining a perfect balance of strength, weight, and performance.

Why Riders & Brands Prefer CNC Over Cast Parts

The difference between cast and billet CNC parts is obvious to anyone who rides hard:

Cast Parts– cheaper, but often brittle, inconsistent, and prone to hidden defects.

Billet CNC Parts – more expensive upfront, but vastly more reliable, precise, and long-lasting.

For individual riders, this means fewer breakdowns and more confidence on the trail. For brands and distributors, it means fewer warranty claims, stronger reputation, and higher customer loyalty.

Sourcing Billet CNC Parts from Taiwan

Taiwan has become a global hub for precision machining and motorcycle part manufacturing. With decades of expertise, advanced CNC technology, and efficient supply chains, Taiwan offers a competitive balance of quality and cost.

At DMS Group Taiwan, we focus exclusively on CNC precision parts for dirt bikes and off-road motorcycles. Our capabilities include:

3-, 4-, and 5-axis CNC machining

High-grade billet aluminum sourcing

Anodizing and surface finishing

Custom logo engraving and branding

Flexible production runs for OEM and aftermarket orders

This combination allows us to serve both small brands needing flexibility and established distributors demanding volume with consistency.

Conclusion

Dirt biking is unforgiving, and your parts need to match the challenge. Billet CNC components provide the strength, precision, and lightweight performance that riders demand and brands rely on. Whether it’s a triple clamp for a pro motocross racer or a custom handguard mount for an aftermarket distributor, billet CNC simply performs better.

At DMS Group Taiwan, we’re proud to be a trusted manufacturing partner for companies worldwide, delivering billet CNC parts that keep riders safe, fast, and in control.

Looking for a reliable supplier of billet CNC dirt bike parts?

Contact DMS Group Taiwan today and see how we can help bring your brand to the next level.

2025/9/25