Engineer Superior Products with a Manufacturing Partner That Understands Titanium Performance

Across industries — from powersports and bicycles to automotive, aerospace, and high-performance industrial machinery — the materials and precision behind your components define both performance and brand reputation. Titanium offers an unmatched combination of strength, light weight, corrosion resistance, and fatigue durability, making it ideal for critical applications where reliability and performance are paramount.

At DMS Group-TW, we specialize in CNC titanium machining, delivering parts that meet the strictest tolerances and demanding engineering requirements. Our expertise ensures that your components are structurally superior, aesthetically precise, and ready to perform in the toughest environments.

Below, we highlight 8 titanium billet components across multiple industries, where precision machining can transform your products and give your brand a competitive edge.

1. Aerospace Brackets & Mounts

The Manufacturing Challenge:

Aerospace components must be ultra-light yet extremely strong, with tight tolerances to fit within complex assemblies.

Our Engineering Solution:

CNC-machined from Ti-6Al-4V titanium, these brackets and mounts achieve micron-level tolerances, maintaining structural integrity while reducing weight — critical for aircraft and UAV performance.

2. Automotive Suspension Links

The Manufacturing Challenge: suspension components endure high loads, vibrations, and fatigue cycles, requiring both precision and durability.

Our Engineering Solution:

Titanium billet machining produces links with optimized geometry for strength-to-weight ratio. Precision pivot points and surface finishes improve reliability and lifespan compared to steel or aluminum.

3. Medical Implants (Bone Plates & Surgical Components)

The Manufacturing Challenge:

Implants need biocompatibility, corrosion resistance, and precise dimensions for surgical fit.

Our Engineering Solution:

Titanium is ideal for medical applications. CNC machining allows complex geometries, smooth surfaces, and tight tolerances, ensuring safe, long-lasting implants and instruments.

4. Industrial Valve Components

The Manufacturing Challenge:

Valves in chemical or energy plants must withstand high pressures, corrosive fluids, and repeated cycles.

Our Engineering Solution:

Machining from titanium ensures corrosion resistance and long-term durability. Precise sealing surfaces and threaded interfaces guarantee leak-free operation in critical industrial systems.

5. Robotics Structural Frames

The Manufacturing Challenge:

Robotic arms and frames need high stiffness-to-weight ratios to maintain precision while reducing actuator loads.

Our Engineering Solution:

Titanium CNC parts provide lightweight yet rigid structures. Complex internal geometries can be machined for vibration damping and integration of actuators, sensors, or cable routing.

6. High-Performance Bicycle Components

The Manufacturing Challenge:

Cycling components must be light, stiff, and fatigue-resistant, while maintaining precise alignment.

Our Engineering Solution:

Titanium cranksets, stem clamps, and dropout plates are CNC-machined for exact tolerances. Strategic material distribution reduces weight without sacrificing stiffness or durability.

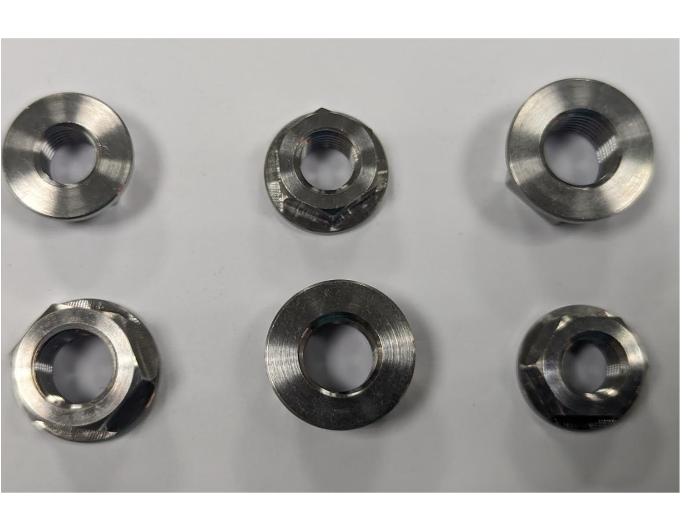

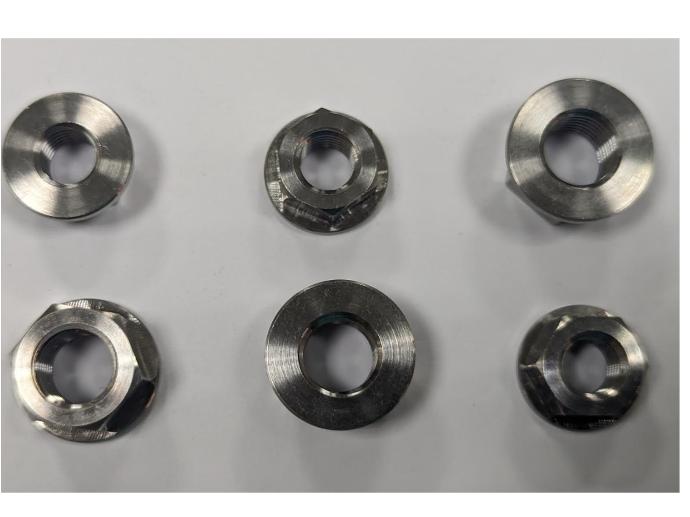

7. Energy & Aerospace Fasteners

The Manufacturing Challenge:

Fasteners in turbines, aerospace engines, and offshore equipment face extreme heat, vibration, and corrosive environments.

Our Engineering Solution:

CNC-machined titanium bolts, nuts, and studs offer superior strength, heat resistance, and corrosion protection, providing reliable long-term service in demanding applications.

8. Custom Tooling & Fixtures

The Manufacturing Challenge:

Manufacturing jigs, molds, and precision fixtures must be accurate, durable, and maintain dimensional stability under repeated use.

Our Engineering Solution:

Titanium fixtures provide lightweight, stable solutions with excellent wear resistance. CNC machining ensures repeatable precision for high-volume production in automotive, aerospace, or electronics assembly lines.

Through multi-axis CNC machining, we can create clamps with optimized internal geometries and controlled wall thicknesses that act as a tuned damping system. The clamping surfaces are precision-textured to grip bars securely without galling or damaging the surface. This provides a tangible improvement in ride quality—a key selling feature you can promote.

Why Partner with DMS Group-TW for Titanium CNC Components?

At DMS Group-TW, we don’t just machine titanium parts — we become an extension of your engineering and production team, helping you turn designs into high-performance, reliable components.

Design for Manufacturability (DFM) Support: We provide expert feedback to optimize your titanium designs for cost-effective production while maintaining maximum strength, precision, and performance.

Prototype to Production Flow: From rapid titanium CNC prototypes to validate form, fit, and function, to seamless scaling into small or large-batch production runs.

Stringent Quality Assurance: Our processes ensure every titanium part meets your exact specifications, with micron-level tolerances and consistent material properties, guaranteeing reliability and repeatable performance.

Material Science Expertise: Deep knowledge in titanium alloys (Ti-6Al-4V, commercially pure grades) and other high-performance metals to achieve the ideal balance of strength, weight, corrosion resistance, and fatigue life for your application.

Explore our dedicated capabilities for the Titainum components to see how we apply this expertise across the sector.

Ready to Elevate Your Component Supply Chain?

Contact Our Engineering Team Today for a Custom Quote

Submit your 3D Models (STEP, IGS) and 2D Drawings (PDF) for a full engineering and cost review.

Looking to optimize existing designs? Ask about our Value Analysis & Value Engineering (VAVE) services to improve performance, reduce costs, and maximize product longevity.