Overview: Pros and Cons of Common RC Chassis Materials

When it comes to building or upgrading your RC car, choosing the right chassis material is one of the most important decisions. It affects everything from performance and durability to cost and handling. In this guide, we break down the most popular RC chassis materials, their pros and cons, and which type of RC driving they’re best suited for.

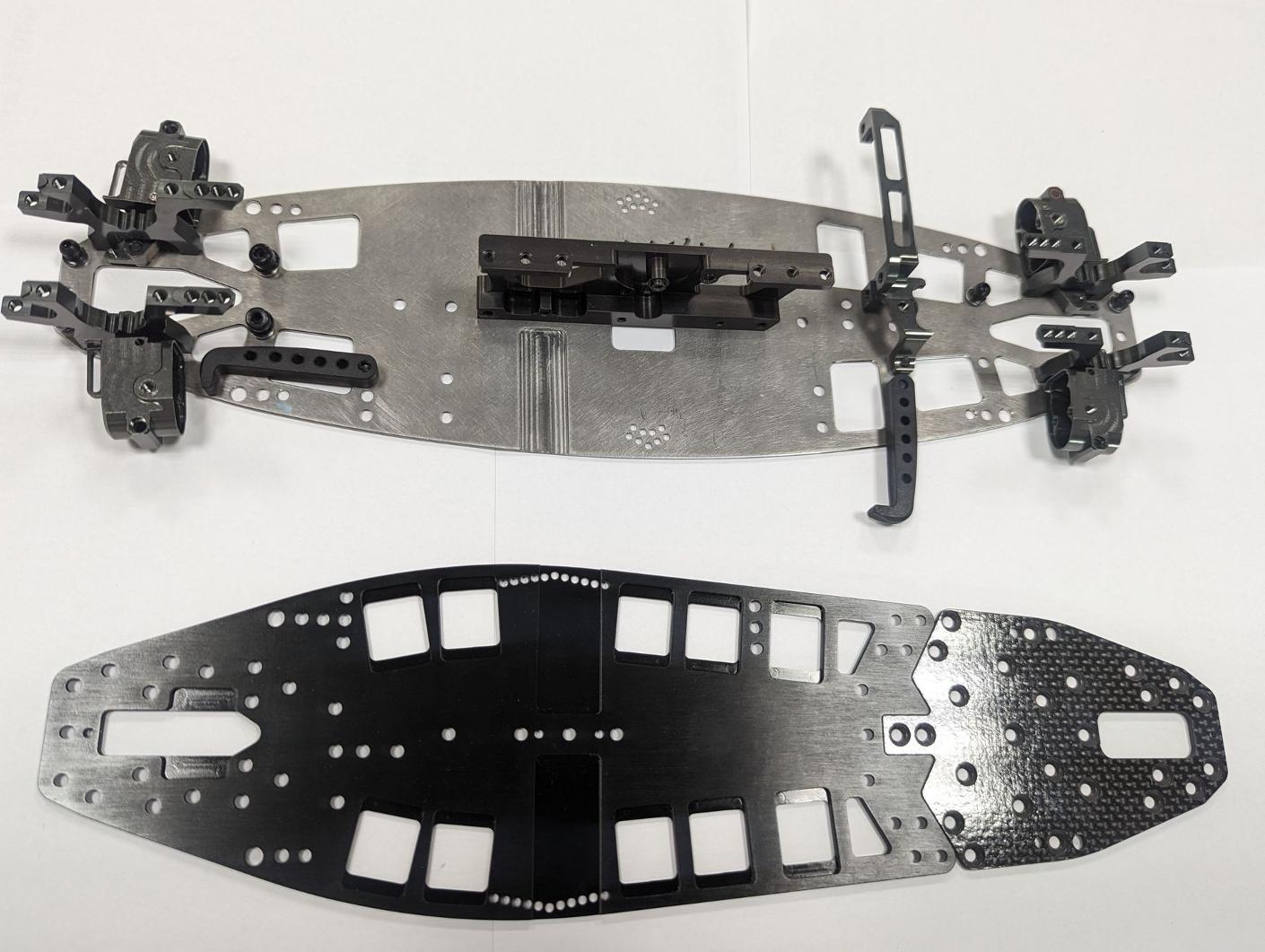

- Chassis Flatness: Why It Matter

- A screw is used to inject the plastic material under high pressure into the mold. The shape of the mold and its design will determine processing factors such as the pressure and flow rate at which the plastic is injected into the mold. Shrinkage rate of the plastic is also considered to ensure the proper size of the final product, and to avoid deformation during cooling off.

- Suspension Tuning Accuracy: If the chassis is warped or twisted, your camber, toe, and ride height settings won't behave consistently across the car.

- Cornering Stability: A flat chassis ensures balanced traction across all four tires, giving you more control through turns.

- Reduced Drag and Friction: In on-road cars, chassis drag against the track can be minimized with a flat, rigid base.

- Carbon fiber and aluminum chassis are usually machined or molded with high precision, offering excellent flatness out of the box.

- Plastic chassis can warp over time—especially with heat, rough impacts, or improper storage.

- Graphite composites may flex slightly but can maintain flatness if properly mounted and braced.

- Lightweight

- Inexpensive

- Flexible—absorbs shocks well

- Easy to replace

- Less rigid—can flex too much under load

- Not as durable in high-impact scenarios

- May crack under repeated stress

- Strong and rigid

- More durable than plastic

- Good heat dissipation

- Looks premium (often anodized)

- Heavier than plastic or carbon fiber

- Can bend on hard impact

- More expensive than plastic

- Ultra-lightweight

- Very rigid—offers precise handling

- High-end racing look and feel

- Corrosion-resistant

- Expensive

- Brittle—can crack under sharp impact

- Hard to repair

- A good middle ground between carbon fiber and plastic

- Lighter than aluminum

- Often cheaper than full carbon fiber

- Not as stiff or durable as carbon fiber

- Can delaminate over time

- Extremely strong and durable

- High wear resistance—good for rough, abrasive environments

- Corrosion-resistant due to chromium content

- Maintains chassis flatness well under stress

- Very heavy compared to aluminum or carbon fiber

- Less common in RC chassis—custom work may be required

- Harder to machine and modify

- Can transmit more vibration without dampening

Flatness is a critical but often overlooked factor in RC chassis performance—especially in racing. Whether you're running on-road or off-road, a perfectly flat chassis helps maintain consistent suspension geometry, proper weight distribution, and predictable handling.

Why Flatness Is Important:

Materials and Flatness:

Pro Tip:

Check your chassis flatness regularly by placing it on a glass sheet or flat setup board. If it rocks or there's visible bowing, it might be time for a replacement—or at least a re-tune.

1. Plastic (Nylon or ABS)

Pros:

Cons:

Best For: Beginners, budget builds, and bashing

2. Aluminum

Pros:

Cons:

Best For: Bashers, trail rigs, and hobbyists who want durability with good performance

3. Carbon Fiber

Pros:

Cons:

Best For: Competitive on-road or track racers where performance is key

4. Graphite Composite / Fiberglass

Pros:

Cons:

5. 420 Stainless Steel

Pros:

Cons:

Best For: Custom builds that prioritize maximum durability over speed, such as heavy-duty crawlers, tank-style RCs, or extreme conditions like mud, rocks, or snow.

Flatness Note:

420 stainless steel is excellent in terms of structural integrity and maintaining flatness under pressure and heat. Unlike plastic or softer metals, it’s highly resistant to warping, making it a solid choice for precision setups in harsh conditions—though at the cost of weight.

RC Chassis Material Comparison Table

| Material | Weight | Durability | Cost | Flatness Stability | Best For |

|---|---|---|---|---|---|

| Plastic (Nylon/ABS) | Light | Medium | Low | Low | Beginners, bashing |

| Aluminum | Medium-High | High | Medium | High | Bashers, rugged use |

| Carbon Fiber | Very Light | Medium | High | Very High | Racing, high precision |

| Graphite/Fiberglass | Medium | Medium | Medium | Medium | Intermediate racing |

| 420 Stainless Steel | Very High | Very High | High | Very High | Heavy-duty, custom builds, extreme terrain |