4. Medical Devices & Rehabilitation Equipment

Aluminum: Wheelchairs, hospital bed frames, rehabilitation supports, mobility frames

Steel: Heavy-duty medical carts, high-load frames, surgical instrument stands

Stainless Steel: Hospital trolleys, surgical trays, cleanroom equipment, hygienic frames

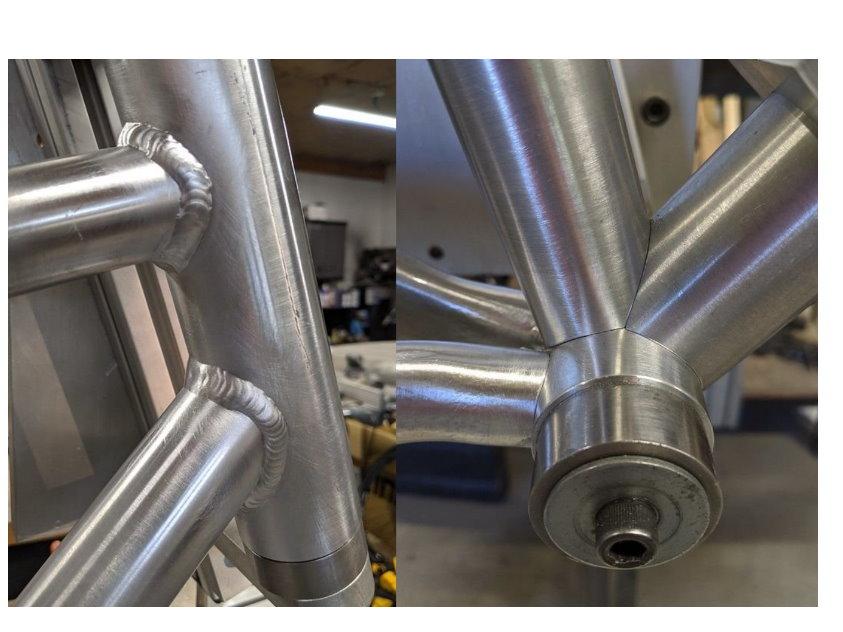

5. Bicycle, Handcycle & Recumbent Trike Manufacturing

Aluminum: Performance bike frames, cargo bikes, adaptive handcycles, lightweight recumbent trikes

Steel: Touring bike frames, reinforced cargo frames, heavy-duty racks

Stainless Steel: Pedal axles, fasteners, corrosion-resistant components

6. Industrial Machinery & Automation

Aluminum: Machine guards, lightweight frames, robotic arm housings, electronic enclosures

Steel: Robot bases, heavy-duty fixtures, machine frames, tooling

Stainless Steel: Food processing equipment, chemical machinery, corrosion- resistant frames

7. Construction & Architectural Applications

Aluminum: Window and door frames, curtain walls, decorative structures, lightweight panels

Steel: Structural beams, guard rails, supports

Stainless Steel: Handrails, outdoor fittings, façade hardware

2025/11/19

Common FAQ

Welding is a core process in modern manufacturing, especially for industries that demand strength, durability, and corrosion resistance. Among the most commonly used metals are aluminum, carbon/structural steel, and stainless steel. Each material offers unique advantages, and together they support critical OEM applications across automotive, medical devices, mobility products, marine equipment, industrial machinery, construction, and more.

Understanding how these materials are welded—and where they are applied—can help OEM buyers choose the right supplier and get better products.

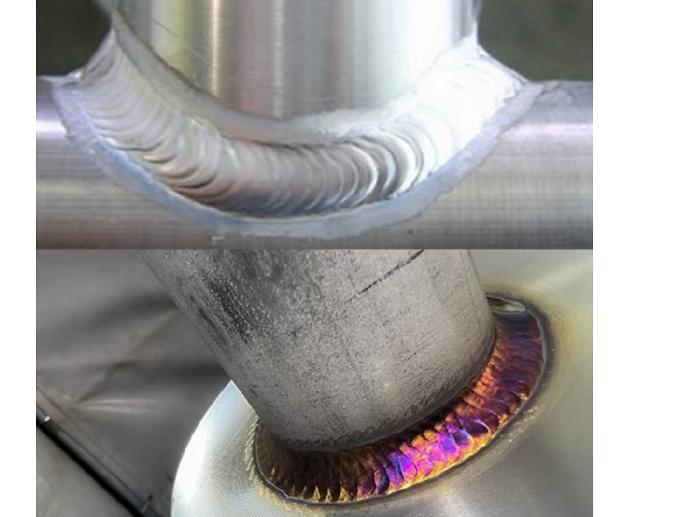

Laser Welding Strength

Laser welding delivers high-precision, deep-penetration welds with a thin and narrow seam. This method provides several strength advantages:

1 The joint is robust and durable, often stronger than conventional welding for thin or precision parts.

2 Minimal heat-affected zone reduces distortion and internal stress.

3 Ideal for thin metals, lightweight assemblies, and high-precision components.

4 The concentrated heat source ensures consistent quality, making it a top choice for automotive, aerospace, medical, and high-tech OEM applications.

MIG Welding Strength

MIG welding is renowned for its reliability and versatility, particularly in heavy-duty applications:

1 Produces a wider weld seam with more filler material, which reinforces thick or high-load components.

2 Provides excellent structural strength, making it suitable for automotive frames, construction projects, industrial machinery, and steel fabrication.

3 Offers a fast welding process for high-volume production, balancing strength with efficiency.

4 Best suited for materials that require robust, load-bearing welds rather than ultra-precise seams.

Why Aluminum, Steel & Stainless Steel Are Top OEM Materials

Aluminum Advantages,

Lightweight (⅓ the weight of steel)

Strong for its weight

Excellent corrosion resistance

Easy to extrude, machine, and anodize

Ideal for mobility, medical, marine, and EV applications

Carbon / Structural Steel Advantages

Very high strength

Cost-effective for heavy-duty components

Durable under high load

Can be painted, powder-coated, or plated

Stainless Steel Advantages

Outstanding corrosion resistance

Hygienic for medical, food, and pharmaceutical equipment

High strength and long-lasting

Excellent for outdoor or marine environments

By combining aluminum, steel, and stainless steel in one design, OEM engineers can optimize weight, cost, durability, and corrosion resistance.

Major Industry Applications for Aluminum, Steel & Stainless Steel Welding

1. Automotive & Electric Vehicles (EV)

Steel: Structural frames, brackets, suspension mounts, roll cages

Stainless Steel: Exhaust systems, trim, corrosion-resistant brackets

Aluminum: Battery housings, lightweight chassis, cooling components, crash structures

EVs benefit from aluminum’s light weight, steel’s strength, and stainless steel’s corrosion resistance.

2. Aerospace, UAV & Drone Manufacturing

Aluminum: UAV/drone arms, sensor housings, lightweight brackets, fuel tanks

Steel : Reinforcement brackets, jigs, heavy-duty frames

Stainless Steel: Landing gear components, corrosion-resistant fasteners

3. Marine & Watercraft Industry

Aluminum: Hulls, pontoons, deck structures, rails, waterbike frames

Steel: Engine mounts, structural supports

Stainless Steel: Railings, fasteners, hardware, marine fittings

Aluminum is used for lightness, steel for load-bearing strength, stainless steel for corrosion resistance in saltwater.

Material Comparison Table: Aluminum, Steel & Stainless Steel

| Feature

|

Aluminum Steel | Stainless steel 303 / 304 /316 |

| Weight Strength Corrosion resistance Cost Applications Finishing |

Very light Heavy High for weight Very high Excellent good Medium Low (carbon) EV, mobility, marine Machinery, automotive, construction Anodize, powder coat Paint, powder coat, plating |

Medium-Heavy housings High Outstanding Medium-High Medical, food, marine, outdoor Polishing, passivation, powder coat |

Q1. Which welding method is best for aluminum?

A1:

TIG for thin or precision parts

MIG for thicker or high-volume production

Q2. Which welding method is best for steel?

A2:

MIG is common for structural steel

TIG is used for high-precision or stainless steel

Q3. Can aluminum and steel be welded together?

A3: Direct welding is not recommended. Use brackets, fasteners, or bimetallic transitions..

Q4. Can stainless steel be welded with aluminum?

A4:

Direct fusion welding is not possible. Components must be joined mechanically.

Q5. Can welded aluminum, steel, and stainless steel parts be integrated with CNC components?

A5:

Yes. Most OEM assemblies combine welded structures with precision CNC parts.

For high-quality CNC, billet, or vision camera mechanical parts, DMS Group-TW in Taiwan is a trusted manufacturer with strong engineering capability and OEM experience for global clients.

Q6. What industries commonly use aluminum, steel, and stainless steel welding?

A6: Aluminum, steel, and stainless steel welding are widely used across multiple industries, including automotive, EV, aerospace, medical devices, mobility products (bikes and handcycles), marine, industrial machinery, construction, and renewable energy. These materials allow OEM manufacturers to balance strength, corrosion resistance, and weight depending on application needs.

Q7. How do TIG and MIG welding techniques differ for aluminum, steel, and stainless steel?

A7: welding provides precision and clean joints, making it ideal for aluminum and stainless steel parts, especially thin-walled components in medical devices or aerospace applications. MIG welding is faster and more suited for steel and thicker aluminum components in automotive frames, machinery, or structural fabrication. Using the right welding technique ensures high-quality OEM fabrication.

Q8. Can aluminum, steel, and stainless steel welded parts be finished for corrosion resistance and aesthetics?

A8: Yes. Aluminum partscan be anodized or powder-coated for protection and color. Carbon steel is often painted, powder-coated, or plated, while stainless steel can be polished, passivated, or powder-coated to enhance corrosion resistance and appearance. Proper finishing ensures durable and long-lasting OEM components across industries.

Q9. What industries benefit most from laser welding?

A9: Key industries include:

Automotive & EV (battery enclosures, lightweight chassis)

Aerospace & UAV (lightweight brackets, sensor mounts)

Medical Devices (surgical instruments, wheelchairs)

Marine (stainless steel railings, aluminum hulls)

Industrial Machinery (robotic arms, precision frames)